Question:

Hi, I am from Coimbatore. I have been working in the garment field for the past 17 years, but I do not worry to ask this question. Still, now I can’t understand how much minimum wages/day is targeted by piece-rate tailors.

For example, if an operation has a SAM value of 0.40 minutes and the minimum wage for shift workers is Rs. 400 in my place, I can fix the cost of that operation to Rs. 0.55 per piece for a 60% efficiency target. But that pcs rate operator asking minimum Rs. 1.5, after long negotiation he agrees at Rs. 1.10.

This means is he expecting to earn a minimum of Rs. 792 per 8 hours or is he planning to work comfortably by achieving 50 pcs/hr at 33% efficiency?

How can I approach this problem in a professional way with my operators?

Answer:

It is true that every employee wants to earn more money. Everyone feels that they are doing hard work and they should be paid more money than their current earning. In a piece-rate production environment, earnings can be increased by setting/earning more money per piece. The piece-rate will impact the garment costing and order FOB. You need to balance the labor costing of a style and operators’ daily earnings.

Let me attempt to answer your question. At the end of this post, I have shared an Excel template download link for calculating operation piece-rate from daily wages, operation SAM and Efficiency.

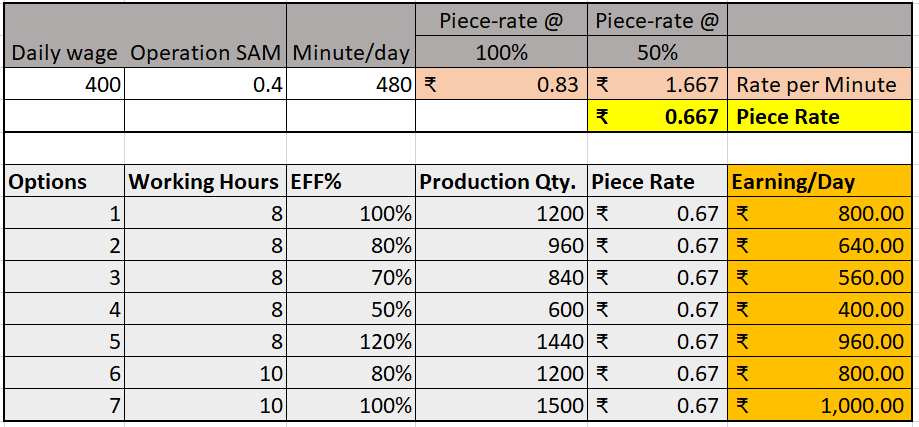

You need to come up with a plan for deciding the minimum pay rate per minute with the average line efficiency. Let’s 50% individual efficiency is an average skill level for the garment sector in India. And minimum wage for garment stitching workers is Rs. 400.00 per day. Based on this you can set up your rate per minute.

@50% efficiency, when an operator works for 480 minutes (full day of 8 hours shift), his produced minutes will be equal to 240 minutes. It means the operator will earn Rs. 400 by producing 240 minutes (600 units in an operation of 0.4 min SAM). If we set up a piece rate based on this, the per minute rate will be Rs.1.67 and for this piece rate for this specific operation will be Re. 0.67

(Note: this is my suggestion. If you know the average efficiency of your factory is higher than 50% set piece-rate according to that).

This can be considered that minimum pay is set for average skilled employees. So, you are paying Rs. 400.00 for operators who are working at 50% efficiency level.

Table-1: Rate per minute and operation rate calculation at 50% efficiency level.

Table-2: Rate per minute and operation rate calculation at 60% efficiency level.

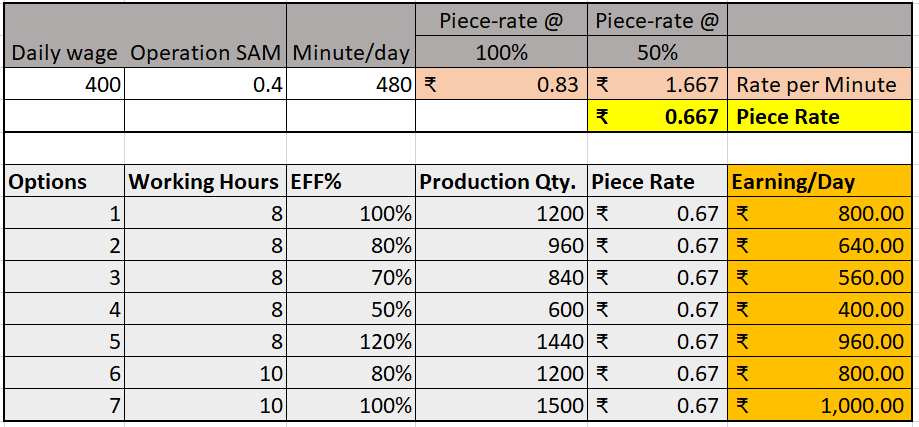

Now considering this as fact, an 100% efficient operator should earn twice the minimum wages. Which means Rs. 800.00 per day (8 hours shift). If an operator works at a 120% efficiency level, he will earn more money and the daily earning amount will be Rs. 960.00

Seeing this rate variation over the average skill and individual skill, you can focus on an employee's accurate efficiency measurement. If you set up accurate standard time and it matches with the operator’s skill, most of the tailors will listen to your logic of deriving piece-rate based on minimum wage, efficiency, and operation SAM.

Explain to them they can even earn more money with the current base rate when they work at a higher efficiency percentage. And daily earnings can be further increased if they work more hours after regular shifts. An example of working OT 2 hours and the earnings amount for this operator is shown in the above example.

I hope this explanation will help you in negotiating the operation rate with piece-rate operators.

Seeing this rate variation over the average skill and individual skill, you can focus on an employee's accurate efficiency measurement. If you set up accurate standard time and it matches with the operator’s skill, most of the tailors will listen to your logic of deriving piece-rate based on minimum wage, efficiency, and operation SAM.

Explain to them they can even earn more money with the current base rate when they work at a higher efficiency percentage. And daily earnings can be further increased if they work more hours after regular shifts. An example of working OT 2 hours and the earnings amount for this operator is shown in the above example.

I hope this explanation will help you in negotiating the operation rate with piece-rate operators.