In this post, I have answered an interesting problem. This question was received from a fabric supplier (knits fabric supplier). Though I have not worked in knitting mills, I have tried to solve the puzzle using my understanding of fabric pricing.

The problem:

Answer:

I am not sure how the supplier was calculating pricing for knit fabrics.

But it is true that if the knit fabric of different GSM passes through the same processes and one adds values of each process in Kg, the resulting cost will be the same per KG for all GSM fabrics. No no way of differentiating fabric prices per Kg for different GSM fabrics.

#2. You might be using a different knitting machine to produce different GSM fabrics. The production rate (Kg per hour) of those machines may be different. So you can add labor costs accordingly. This may result in a different fabric price.

#3. If you are including post-knitting processing costs, please check how you apply labor cost/processing cost. Is it per meter or in Kg? If it is in meters then you will get a little variation in costing of the fabrics.

I hope this will give you an idea.

After reading my answer, the supplier communicated the same with the buyer. The buyer also understood the reason for getting the same pricing for different fabrics.

Problem-2:

Answer:

For example, I have considered knit fabric price per Kg is Rs. 350. And another important parameter for conversion is fabric width. For example, the fabric width is considered as 1 meter.

The problem:

My customer needs prices/kg of Single Jersey fabric in different GSM viz 140, 150, 160 & 180.

When I calculate the cost of yarn per kg and other processing charges, I get the same price for all GSM fabrics. How should I differentiate the cost for respective GSMs? Kindly help me correct the calculation of prices.

Answer:

I am not sure how the supplier was calculating pricing for knit fabrics.

But it is true that if the knit fabric of different GSM passes through the same processes and one adds values of each process in Kg, the resulting cost will be the same per KG for all GSM fabrics. No no way of differentiating fabric prices per Kg for different GSM fabrics.

Therefore, the result the supplier was getting is correct.

I would suggest checking these variables to come up with accurate fabric pricing per Kg of different GSMs.

#1. I am sure you will be using different counts of threads/yarns for knitting different GSM of fabrics. And yarn price per kg may slightly vary based on yarn count. If they do, you can use that data for estimating fabric prices. By using this variable you will have a different price for different GSM fabrics.

I would suggest checking these variables to come up with accurate fabric pricing per Kg of different GSMs.

#1. I am sure you will be using different counts of threads/yarns for knitting different GSM of fabrics. And yarn price per kg may slightly vary based on yarn count. If they do, you can use that data for estimating fabric prices. By using this variable you will have a different price for different GSM fabrics.

#2. You might be using a different knitting machine to produce different GSM fabrics. The production rate (Kg per hour) of those machines may be different. So you can add labor costs accordingly. This may result in a different fabric price.

#3. If you are including post-knitting processing costs, please check how you apply labor cost/processing cost. Is it per meter or in Kg? If it is in meters then you will get a little variation in costing of the fabrics.

I hope this will give you an idea.

After reading my answer, the supplier communicated the same with the buyer. The buyer also understood the reason for getting the same pricing for different fabrics.

Problem-2:

For example, my prices of Interlock knitted fabrics for all gsm (as the yarn count is the same). I arrive at the same price of fabric in kgs. I informed the buyer that the yardage will differ for different gsm.

Now the buyer is asking for the differential prices of respective gsm to be calculated as per yardage?

The buyer is now asking me for the following fabrics:

1. S/J-140 GSM

2. S/J-160 GSM

3. INT-190 GSM

4. INT-200 GSM

5. INT-210 GSM

6. INT-220 GSM

7. VELOUR-240 GSM

8. VELOUR-260 GSM

9. VELOUR-280 GSM

1. S/J-140 GSM

2. S/J-160 GSM

3. INT-190 GSM

4. INT-200 GSM

5. INT-210 GSM

6. INT-220 GSM

7. VELOUR-240 GSM

8. VELOUR-260 GSM

9. VELOUR-280 GSM

Answer:

If you calculate fabric prices in meters (or per yard), you will get a different price value for a yard of fabric.

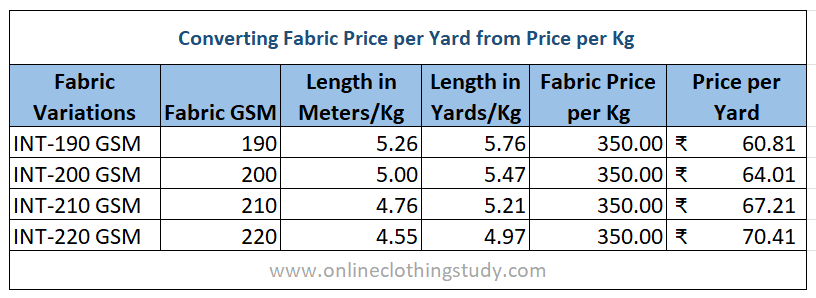

I have written one article on converting price from price/kg to price/meter (or yardage). Please check that article to know the conversion method. Here, I will be sharing the price per yard of four different GSMs of interlock fabrics from the above list.

For example, I have considered knit fabric price per Kg is Rs. 350. And another important parameter for conversion is fabric width. For example, the fabric width is considered as 1 meter.

In the following table, I have first converted the 1 kg fabric into meters using the below formula. Later, Fabric length is converted into yards from meters.

Formula:

Weight (in grams) = Fabric length (in meters) X Fabric width (in meters) X Fabric GSM

Don't forget to add allowances in your price (quote) that will happen due to GSM variation in the fabric roll. Or you can tell your buyer that you can share the price in yardage but the actual invoice (selling) will be done based on KG. This will help both parties in terms of financials.