The computer aided design (CAD) is an essential tool for the digital pattern making and product development in the apparel and sewn product industry. The CAD system can be further linked to the automatic cutting software (CAM). But yes, CAD system can be used independently without installing an automatic cutting system.

The main objective of the CAD system is making digital patterns, 3D simulation of the garment sample, pattern grading, checking the garment fitting, and quick correction of patterns based on the fit comment.

We have listed down some of the benefits of having the CAD system in-house in the apparel industry. These benefits are illustrated by well-known CAD solution providers. By installing CAD software, you can be benefited in the following areas.

1. Eliminate manual steps in the design process. You can reduce manpower and improve the performance of the pattern making department.

2. Draft the garment pattern from scratch. Drafting a 2D pattern in the computer can be done by using CAD tools provided by the CAD provider.

3. Digitize existing hard-copy patterns. You might have made the paper patterns which is ready with you and approved by the buyer. You can digitize those hard-copy patterns in the CAD and store digitally.

4. Edit and finalize existing digital patterns easily. Pattern editing, pattern grading, and checking of the digital patterns can be electronically.

5. Store and restore digital patterns easily. You can save your designs (patterns) developed in the CAD and easily restore when you need. Copy and paste of the existing pattern can be done.

6. Visualize measurements of different styles and gain control of internal features such as notches, buttons, and drill holes.

7. Walk a pattern while you correct the shape, add or adjust details, and import patterns with every layer intact.

8. Darts, seam allowance, special corners, advanced measurement techniques, pleats, curves, and facings, are all fitted to trade, to meet the needs of customers across a wide range of product and style types.

Also read: Garment Pattern Making Software for Your Clothing Business

9. Importing and exporting of patterns file to and from all major CAD formats is possible.

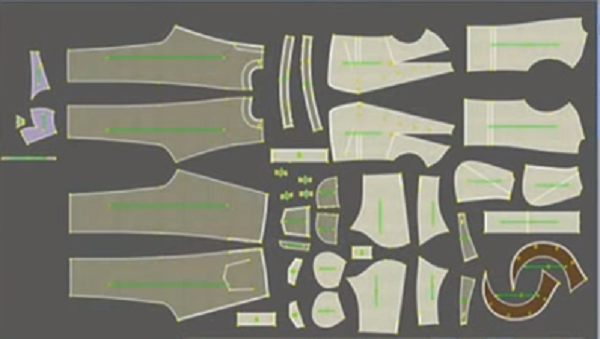

10. Make digital marker. After pattern making, you can prepare the marker with hundreds of combination and see on the computer screen which combination gives you the best utilization of fabric. It is called as nesting. You can take printout of the maker and use the maker in the fabric lay for cutting

11. Mini-marker printout. You can take a printout of the mini-marker, which is used for material consumption calculation. The same can be filed in the production file and given to vendors or CMT factories.

12. Estimate material consumption. In manual method fabric consumption is calculated based on the patterns and a marker of the average size garment. With the CAD system, you can calculate size wise fabric consumption in various marker-ways. This would help you optimize the fabric consumption and cost in fabric sourcing. Even you can prepare a separate marker for the different fabrics width.

All these benefits altogether reduce the sample development time, reduce the cost of sample development, and better fit for some kind of garments.

The advantages of the CAD system are not limited to the above points only. It has many other benefits as well. A novice can learn pattern making faster by using the CAD system.

Image source: Optitex/Youtube

We have listed down some of the benefits of having the CAD system in-house in the apparel industry. These benefits are illustrated by well-known CAD solution providers. By installing CAD software, you can be benefited in the following areas.

1. Eliminate manual steps in the design process. You can reduce manpower and improve the performance of the pattern making department.

2. Draft the garment pattern from scratch. Drafting a 2D pattern in the computer can be done by using CAD tools provided by the CAD provider.

3. Digitize existing hard-copy patterns. You might have made the paper patterns which is ready with you and approved by the buyer. You can digitize those hard-copy patterns in the CAD and store digitally.

4. Edit and finalize existing digital patterns easily. Pattern editing, pattern grading, and checking of the digital patterns can be electronically.

5. Store and restore digital patterns easily. You can save your designs (patterns) developed in the CAD and easily restore when you need. Copy and paste of the existing pattern can be done.

6. Visualize measurements of different styles and gain control of internal features such as notches, buttons, and drill holes.

7. Walk a pattern while you correct the shape, add or adjust details, and import patterns with every layer intact.

8. Darts, seam allowance, special corners, advanced measurement techniques, pleats, curves, and facings, are all fitted to trade, to meet the needs of customers across a wide range of product and style types.

Also read: Garment Pattern Making Software for Your Clothing Business

9. Importing and exporting of patterns file to and from all major CAD formats is possible.

10. Make digital marker. After pattern making, you can prepare the marker with hundreds of combination and see on the computer screen which combination gives you the best utilization of fabric. It is called as nesting. You can take printout of the maker and use the maker in the fabric lay for cutting

11. Mini-marker printout. You can take a printout of the mini-marker, which is used for material consumption calculation. The same can be filed in the production file and given to vendors or CMT factories.

12. Estimate material consumption. In manual method fabric consumption is calculated based on the patterns and a marker of the average size garment. With the CAD system, you can calculate size wise fabric consumption in various marker-ways. This would help you optimize the fabric consumption and cost in fabric sourcing. Even you can prepare a separate marker for the different fabrics width.

All these benefits altogether reduce the sample development time, reduce the cost of sample development, and better fit for some kind of garments.

The advantages of the CAD system are not limited to the above points only. It has many other benefits as well. A novice can learn pattern making faster by using the CAD system.

Image source: Optitex/Youtube