Curious about the behind-the-scenes machines powering the fashion industry?

Every piece of clothing you see on the store shelf came out of a textile machine. From spinning machines that twist raw fibers into yarn to looms that weave fabrics into patterns, these machines are the workhorses of the fashion manufacturing process.

Let's be real…

Learning about textile machinery isn't just for engineers. Fashion industry professionals that understand these basics make better production, quality, and sourcing decisions.

|

| Image source: https://unsplash.com/ |

In this guide we have coveed the following details:

- The Core Components of Textile Machinery

- Why Electric Motors Matter More Than You Think

- Spinning and Weaving Essentials

- How to Evaluate Machinery for Quality Production

The Core Components of Textile Machinery

Textile machinery is a complex system of many interconnected parts that work together. These components are carefully designed to perform specific tasks needed to transform raw materials into finished textiles.

There are several different types of key components, including mechanical, electrical, and control systems. There is, however, one type of component that deserves particular attention.

The single-phase electric motor.

This type of motor is the power source for smaller textile machinery operations. From sewing machines to small looms, the single-phase electric motor powers all the important equipment used in smaller operations. A quality TEC electric motor can make a significant difference between productive runs and production grind to a halt due to frequent breakdowns and maintenance. Single-phase electric motors are extremely popular as they are able to connect directly to the standard electrical supply without the need for complex wiring.

Is that important?

Yep, you bet.

Why Electric Motors Matter More Than You Think

Electric motors may be the unsung heroes of the textile manufacturing world. The U.S Energy Information Administration reports that machine drives in the textile industry can account for as much as 25% of total delivered energy use in the textile industry. That is no small operating cost.

So, what does that mean to the fashion industry professional?

The motor you choose has a direct impact on the efficiency of your production and therefore the cost. Motors that run inefficiently waste energy and increase fabric tension inconsistency. This tension inconsistency will then translate to product defects which the consumer will see when they purchase the garment.

The main applications for single-phase electric motors are as follows:

- Small-scale manufacturing operations

- Individual sewing machines

- Light-duty weaving machines

- Auxiliary textile processing equipment

For large-scale industrial textile production, you will likely find three-phase motors and motors of far higher power ratings. But many fashion businesses begin with single-phase equipment and operations and grow from there.

Spinning and Weaving Essentials

The global textile machinery market size was valued at over $30 billion in 2024. Spinning equipment accounts for more than 40% of that value. So, it is extremely important for industry professionals to have at least a rudimentary understanding of these machines to be able to make educated production capability decisions.

Spinning Machinery

Spinning machines are one of the critical types of textile equipment that form the first stage in the conversion of raw fiber into usable yarn or thread. The spinning process involves drawing out fibers, twisting them together to add strength, and then winding the resulting yarn onto bobbins or spools.

Modern spinning machines have precise motor systems that control tension and speed. Small variations in motor performance can lead to noticeable variations in yarn quality. This is why it is important to understand motors.

There are several types of spinning machines, including ring spinning machines, open-end spinning machines, and air-jet spinning machines. Each produces yarn with unique characteristics and has different motor requirements.

|

| Image: Spinning machine |

Weaving Machinery

Weaving machines interlace two or more sets of yarns or threads to produce fabric. These machines use various patterns and tensions of the weft (horizontal) and warp (vertical) threads to create different types of textiles.

Weaving machines require precise motor control for moving the shuttle back and forth and regulating tension to ensure the fabric's density remains consistent. Variations in motor performance can lead to uneven density across the fabric.

|

| Image: Weaving machine |

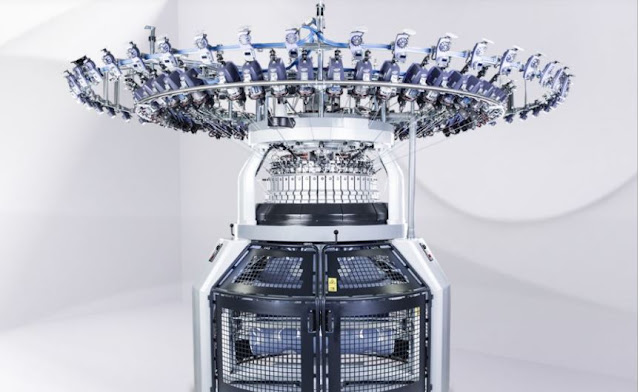

Knitting Machinery

Knitting machines produce fabric by interlocking loops of yarn. Knitting machines range from flatbed machines to circular knitting machines and others.

Motor speed is critical in determining the consistency of the stitch. Variable speed drives linked to quality motors offer the operator a high level of control over the knitting process.

How to Evaluate Machinery for Quality Production

When evaluating textile machinery (whether for purchasing or assessing a supplier), here are some key considerations.

Motor Quality and Specifications

Pay attention to what motors power the machinery. Are they a well-known motor brand? Do they have a clearly indicated efficiency rating? Do the motor specifications meet the requirements for the given machine?

Build Construction

Look at the frame, housing, and general construction materials. Quality machines are typically built with heavy-gauge steel or cast iron for stability. Lighter and flimsier equipment often indicates corners have been cut that will affect long-term performance.

Control Systems

Modern textile machinery will use electronic controls. Look for equipment with intuitive interfaces and programmable settings. These features increase production consistency and reduce the potential for operator error.

Maintenance Access

Good design of textile machinery allows the operator or service technician to access wear components. Motors, belts, bearings, and more need to be serviced regularly. Equipment that makes maintenance and service difficult will have a higher cost of ownership over its lifetime.

Understanding Energy Consumption

The majority of the cost of textile manufacturing is electricity for the production processes. Textile industry energy consumption can amount to around 77% of total factory electricity use.

Electricity costs are a significant operating cost and one that motor efficiency has a big impact on. A high-efficiency motor is more expensive but uses less energy. High-efficiency motors also tend to last longer and require less maintenance over their lifetime.

Pay close attention to motor efficiency class. Premium efficiency motors can save 2-8% on energy consumption over the standard efficiency motors. These are savings that add up over many years of use.

Maintenance Basics Every Professional Should Know

Textile machinery maintenance is not rocket science. But it is a task that, when not carried out with regularity and attention, can be the cause of breakdown and loss of production.

Fashion professionals who have at least an understanding of maintenance basics can more effectively manage their supplier relationships and catch quality issues earlier.

- Lubrication schedules matter. Motor and bearings need to be properly lubricated at regular intervals defined by the manufacturer. Neglecting this maintenance results in premature wear and costly downtime.

- Belt tension affects everything. Drive belts need to be regularly checked for tension and wear. Loose belts slip and lead to a loss of efficiency. Overtightened belts overwork bearings and motors.

- Clean equipment performs better. Dust and lint accumulate on machinery from textile operations. This will affect motor cooling and can lead to motor overheating. Regular cleaning improves the lifetime of equipment.

- Listen to your machines. Strange sounds can be an early warning of problems developing. Grinding, squealing, knocking, or other unusual noises are a sign of further investigation before the small problem becomes a major failure.

Conclusion:

Textile machinery components may seem like the type of information industry professionals don't need to worry about. But knowing the basics of the machines powering your supply chain and your production give you a serious competitive advantage. You can better evaluate your suppliers, spot quality problems earlier, and make more informed decisions regarding production partnerships.

The key takeaways are simple.

- Electric motors power most of the textile production process.

- The quality of the motors affects fabric consistency and energy costs.

- Single-phase motors are useful and common in smaller operations.

- Maintenance is important to ensure the continued longevity of the machinery and production processes.

- Machinery evaluation skills lead to better supplier selection.

The textile machinery market is only going to become more and more automated and linked to smart technology systems. But the foundations are always the same. Quality components, well-maintained, that produce quality textiles.

Related articles:

Diffenrent Types of Sewing Machines Used in Apparel Production

List of Essential Machines for Starting a Garment Manufacturing Business