Author: Aayushi Kumar

All the information needed to create the drawdown yourself, or to weave the structure straight away, is contained in the three components- threading, treadling and tie-up matrix.

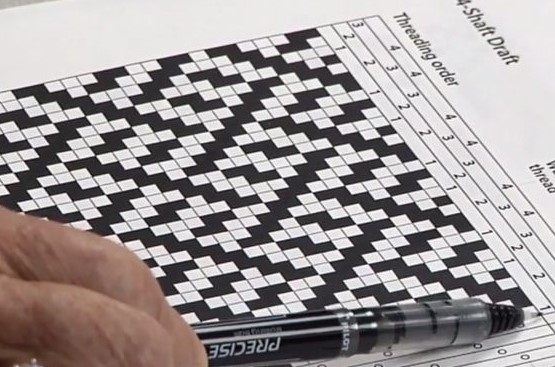

The diagram above shows the very same draft as seen for the tie-up format., however, it has now been converted to a lift plan format. Note the differences- the shafts (harness) and the columns of the lift plan are connected by right-angled arrows.

For a table/dobby loom you follow a lifting plan, usually moving levers for each shaft that must be raised. Every row in the lift plan corresponds to one weft pick, while the columns correspond directly to the shaft that gets lifted. Note that the treadling section no longer represents the treadles that have to be pressed – they now show which shafts have to be raised on each row.

Related Post:

References

A lot of new weavers find it tricky to read the weaving drafts. These drafts have been transferring the information about the weave pattern, type of loom, threading, tie-up plan, lifting plan etc from one generation to the other. Broadly, there are two ways in which weaving patterns are drafted on paper-

- Tie-up Format

- Lift up plan.

What is the difference?

There is one straightforward difference between the two formats – Tie-up format is prepared if you are working on a floor loom having multiple treadles; upon pressing those treadles, the harness is either lifted up or sinks down depending on the type of loom (rising shed and sinking shed loom).

Lift plan drafts are mainly associated with dobby looms and table looms. A dobby can be mechanical or electronic, but each harness can be selected without using treadles. In a manual dobby loom, the pegs select the harness to be moved. Whereas in computer-assisted dobby loom a computer program selects which harness is to be moved. In either case, the harnesses are lifted or sunk by either leg power on a dobby pedal or other power sources.

Because no treadles are involved, a lift plan draft is also a good format for table loom weavers.

The dobby and table loom weavers do have an advantage here because every tie-up draft can be rewritten as a lift plan draft, but not the other way around!

The dobby and table loom weavers do have an advantage here because every tie-up draft can be rewritten as a lift plan draft, but not the other way around!

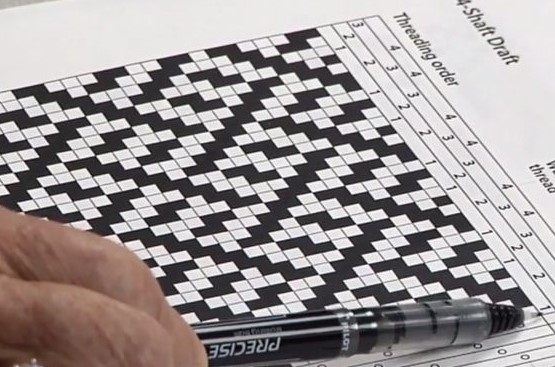

Representation of the tie-up format

| Figure-1: Representation of Tie-up format |

The figure above is a standard format of tie-up. In this presentation, the weaving draft consists of four essential elements which are as follows-

- Horizontal Matrix: Represents threading of the loom. It tells you how you need to thread your warp for a specific pattern. The number of rows denote number of shafts or harness. The threading is usually read from right to left.

- Vertical Matrix: In case of a floor loom, treadling is written vertically and each column corresponds to one treadle. The treadles are numbered from left to right. This matrix shows the sequence in which treadles are to be pressed to get the desired pattern.

- Junction Matrix: This junction at the top right corner shows how the harness (on which threading is done) and the treadles are linked via lams.

- Draw Down Area: A schematic representation of the cloth itself.

All the information needed to create the drawdown yourself, or to weave the structure straight away, is contained in the three components- threading, treadling and tie-up matrix.

Representation of the lifting plan format

| Figure-2: Lifting plan format. |

For a table/dobby loom you follow a lifting plan, usually moving levers for each shaft that must be raised. Every row in the lift plan corresponds to one weft pick, while the columns correspond directly to the shaft that gets lifted. Note that the treadling section no longer represents the treadles that have to be pressed – they now show which shafts have to be raised on each row.

Related Post:

References

- Hand Weaver’s Pattern Directory by Anne Dixon

- Woven Textiles: A Designer’s Guide by Sharon Kearley

- Lift plans- An article by Cally Booker http://weavingspace.co.uk/

About the Author:

Aayushi Kumar, an NIFT, Kolkata graduate, and Co-founder of Ednam Solutions Pvt Ltd is working in the field of female healthcare and hygiene, making smart garment.

Her interests include sustainable fashion, functional garments and luxury brand management.