Health of a Garment Factory

In present scenario it is very important to have real-time information about health of your factory. Health of a Factory means the performance of vital business KPIs against they were planned. Garment factories follow some guidelines/measures/scales against which their performance is measured. In this post, we will see how garment factories can measure the health of the factory through Cost-per-Minute calculation and analysis.It is very important to have an eye on functioning of an organization and daily profit and loss, otherwise after some time, the expenses will be much higher than the planned expenditure. Industrial engineering department in collaboration with HR and accounts should follow up daily produced minutes, available minutes and total expenses done by the factory.

Generally, industrial engineers in a garment factory use various tools such as KPIs by which they keep an eye on functioning of the organization.

Tools to Measure Health of a Garment Factory

The major KPIs in garment industry is listed below. I have taken some of the KPIs and the list can vary based on the type and requirement of the organization.- Factory Efficiency

- Man to Machine Ratio

- Cost Per Piece

- Cost Per Minute

- Cut to Ship Ratio

- PO to Ship Lead Time

To know more about these KPIs read this article.

Cost Per Minute (CPM) Calculation

You may already know basic information about these KPIs. They are used in most of the organizations. Let me show you the calculation method of Cost Per Minute in a factory. This KPIs seems prominent to me and it summarizes all other KPIs. Cost per Minute is inversely proportional to Health of an Organization. It means if CPM is low health of factory is good and vice versa.CPM = (Total Operational Expenses/ Total Minutes Produced)

Total Operational Cost = (Manpower Cost + Overhead Cost)

Total Minutes Produced = (Total OK Pcs Produced X SMV)

In the above formula, we can see that in order to reduce CPM of a factory we either we need to reduce expenses, or we need to increase total produced minutes.

So In directly it also monitors KPIs like Cost/Piece, Factory Efficiency and quality KPIs like DHU, First time Right (FTR).

Now let’s see how to calculate CPM of a garment factory.

Cost per minute can be calculated hourly, daily, weekly, or monthly but I would recommend its calculation on daily basis and matching it with budgeted CPM.

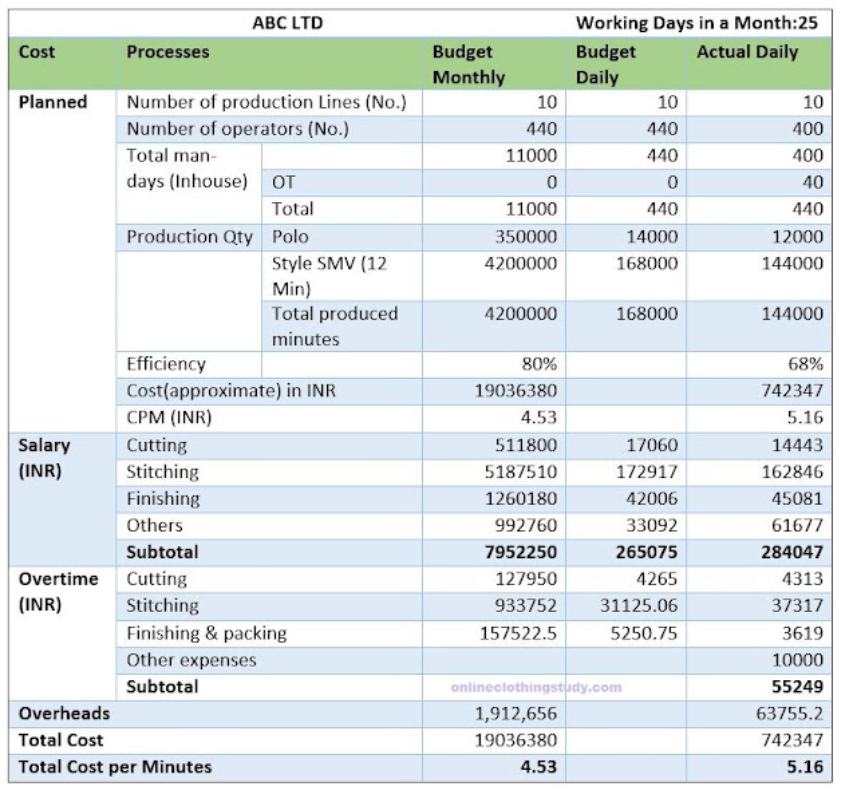

Table: Cost per Minute Calculation

In the above table, we can see the projected cost per minute was INR 4.53 but actual cost per INR 5.16 which is higher than the projected CPM.

From this data we can check the planned cost per polo shirt is INR 54.36 and actual cost per polo shirt is INR 61.92.

Example Graphs:

Chart-1: Monthly CPM trend chart

Chart-1: Monthly CPM trend chart

Chart-2: Daily CPM trend chart

Table given above is self-explanatory and data required can be easily found from daily MIS. Even the similar format can be made in software based daily production reports.

Related post: How to reduce Cost per minute of a Factory

Updated on: 11/05/2023

Publication date: 27/08/2020